Funkenfreies Werkzeug

Bei der Anwendung dieser Werkzeuge haben brenzliche Situationen keinen Funken Hoffnung. Kreiert für die anspruchsvollsten aller Einsatzgebiete, bieten dir unsere Tools vor allem zwei Dinge: Zertifizierte Qualität und Sicherheit, auf die du dich feuerfest verlassen kannst.

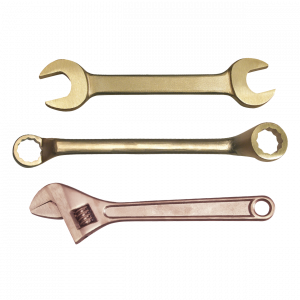

Doppelmaulschlüssel, funkenfrei

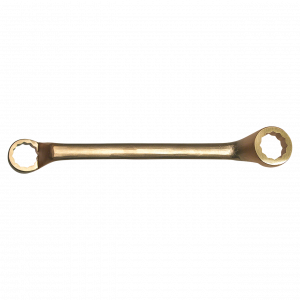

Doppelringschlüssel, gekröpft, funkenfrei

Rollgabelschlüssel, funkenfrei

Schlagringschlüssel, funkenfrei

1/2" Steckschlüsseleinsatz, 6-kant, funkenfrei

1/2" Knarre, umsteckbar, funkenfrei

1/2" Verlängerung, funkenfrei

Sechskant-Stiftschlüssel, funkenfrei

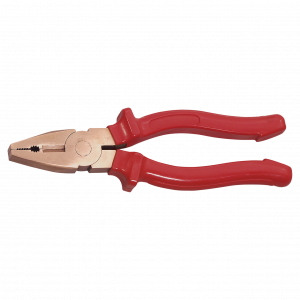

Kombinationszange, funkenfrei

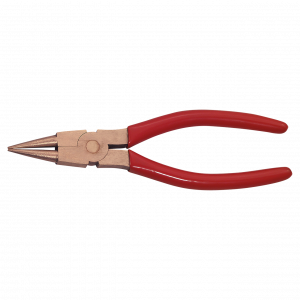

Flachrundzange, funkenfrei

Seitenschneider, funkenfrei

Rundzange, funkenfrei

Flachzange, funkenfrei

Eckrohrzange, funkenfrei

Wasserpumpenzange, funkenfrei

Kantenzange, funkenfrei

Werkstatt-Schraubendreher, funkenfrei

PH Schraubendreher, funkenfrei

Schlosserhammer, funkenfrei

Vorschlaghammer, funkenfrei

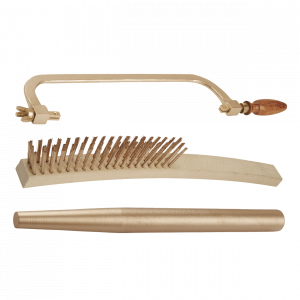

The perfect Maße

Die Sicherheit liegt im Material: Wir stellen unsere Werkzeuge aus extrem verschleißbeständigen Nicht-Eisen-Legierungen her - entweder Sonderbronze oder Kupfer-Beryllium, welche vom Bundesamt für Materialforschung geprüft werden. Beide Sorten zeichnen sich durch ihre Null-Funken-Tooleranz sowie hohen Korrosionswiderstand aus. Zudem sind sie antimagnetisch und ein perfekter Kompromiss aus Dehnbarkeit und Härte.

Fast alle unsere funkenfreien Werkzeuge werden nach Holz- oder Kunststoffmodellen abgegossen. Damit dein Werkzeug mustergültige Proportionen besitzt, gehen wir nach einem ganz bestimmten Prinzip vor: Wir halten die Daten eines optimalen Abgusses fest und orientieren uns daraufhin durchgängig an ihnen. So garantieren wir stets Idealwerte und höchste Qualitätsstandards.

Tested höchstpersönlich

Das hohe Level bei Material und Fertigung macht unsere Werkzeuge zu idealen Begleitern für Bereiche, in denen ein hohes Feuer- und Explosionsrisiko herrscht - wie etwa in der Chemieindustrie oder beim Pipeline-Bau. Um absolut sicher zu gehen, werden unsere Tools sowohl in einem offiziellen- als auch in einem eigenen DIN-Verfahren geprüft. Jede Charge wird von uns stichprobenartig auf mechanische Eigenschaften und chemische Zusammensetzung untersucht. Sollte dir das nicht ausreichen, kannst du bei uns gerne eine weitere Prüfung samt Röntgenbild durchführen lassen.